Pu Leather Processing Technology

Cutting: Cut the PU leather according to the product design drawings to ensure accurate size.

Sewing: The cut PU leather is sewn through sewing machines and other equipment to form the basic structure of the product.

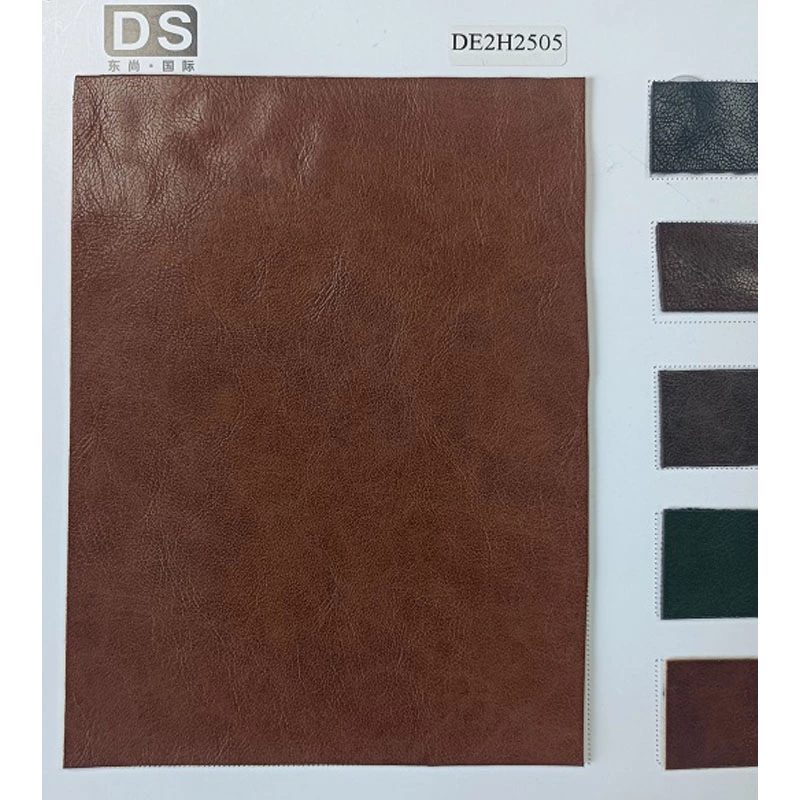

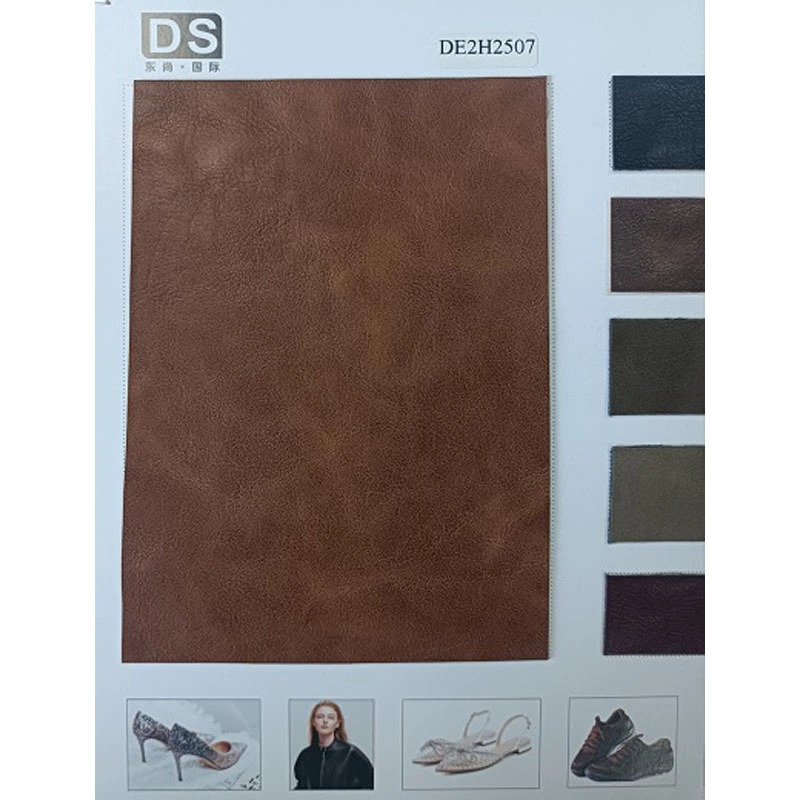

Embossing: The PU leather is embossed through molds and embossing machines to give it texture and pattern.

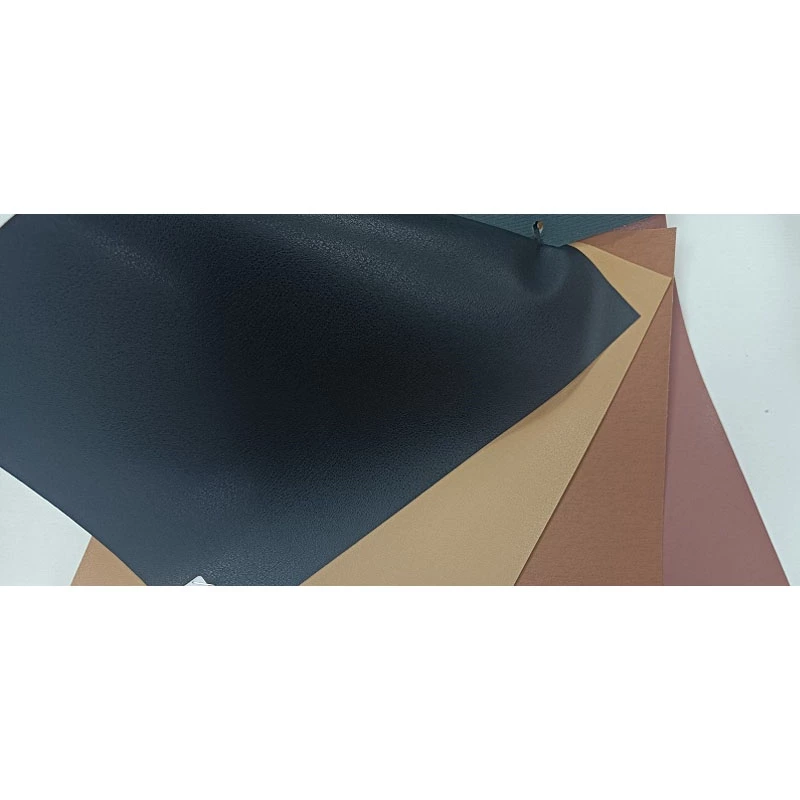

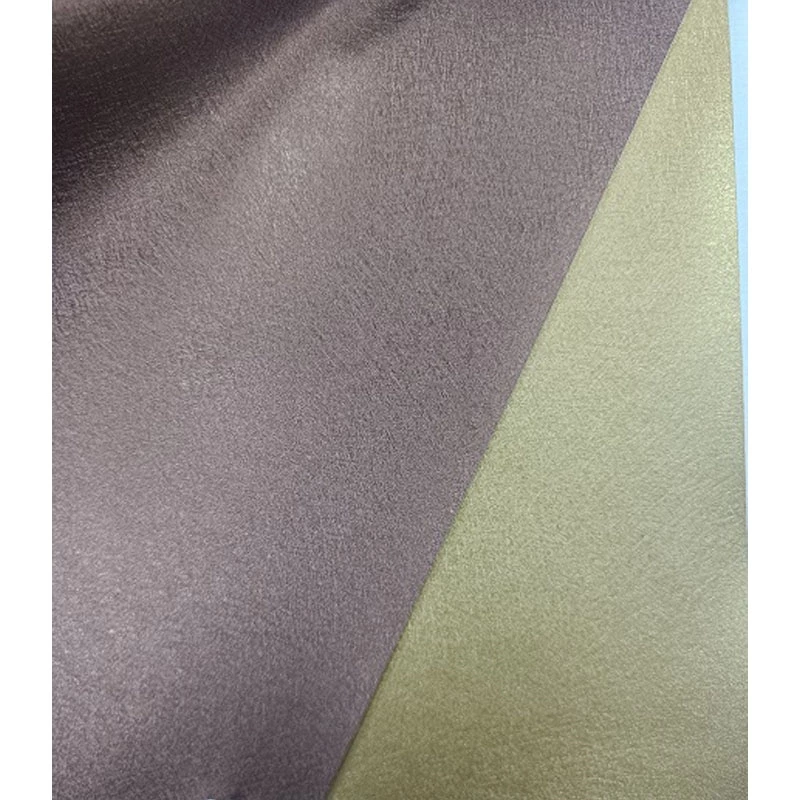

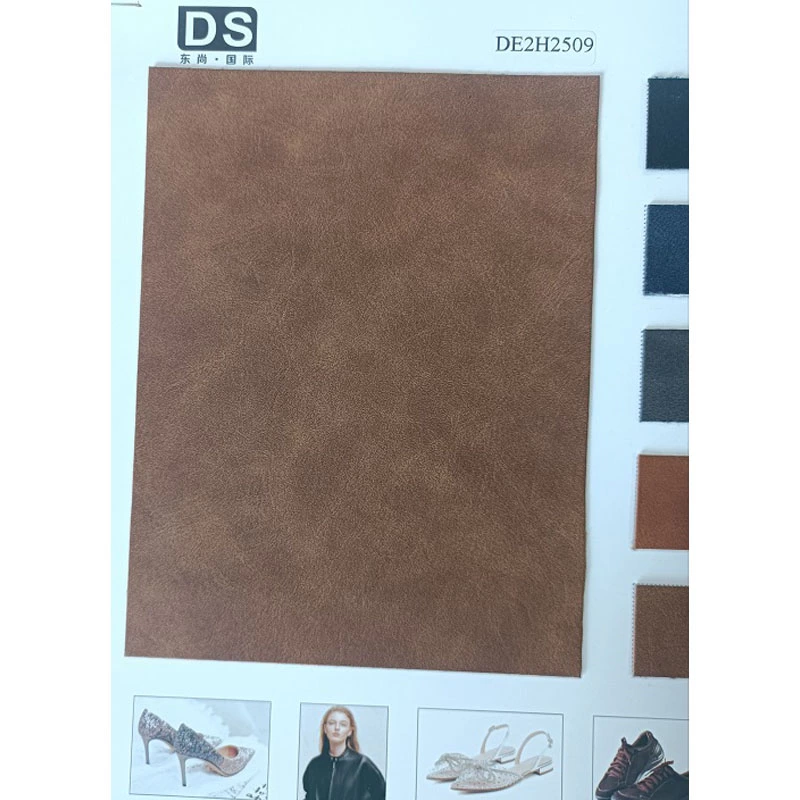

Printing and dyeing: PU leather can be printed or dyed as needed to achieve a variety of appearance effects.

Coating: Surface coating of PU leather increases the wear resistance and waterproofness of the product.

Molding: The PU leather treated by the above process is further molded to make various finished products.