Leather Identification: The Main Differences Between Pu Leather And Pvc Leather

Synthetic leather other than general genuine leather is collectively referred to as PVC and PU leather, which are called artificial leather or imitation leather. PVC and PU are both polyvinyl chloride (one of the plastics), but the manufacturing processes of the two products are different.

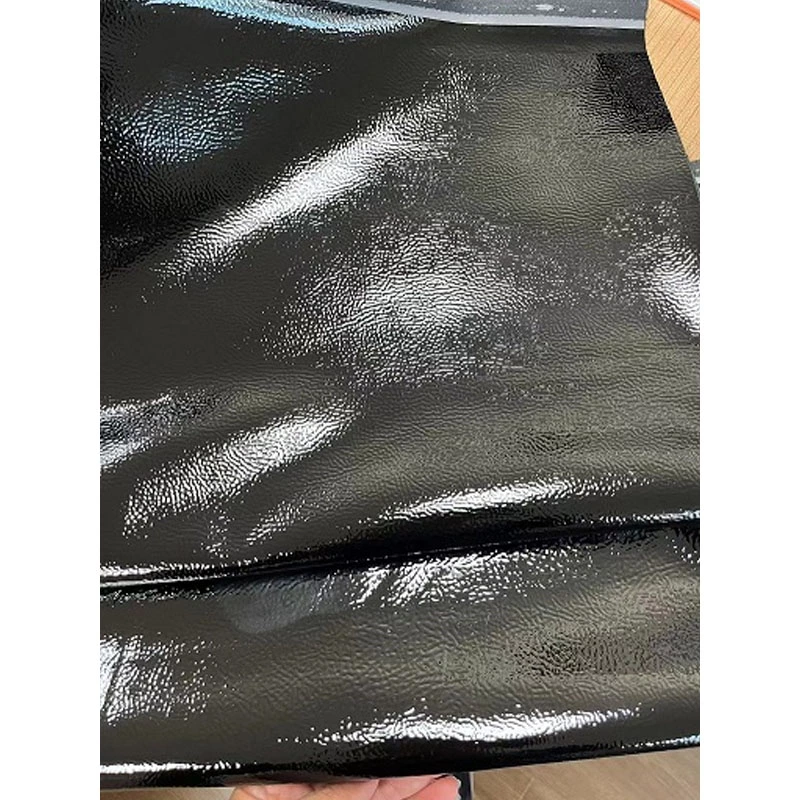

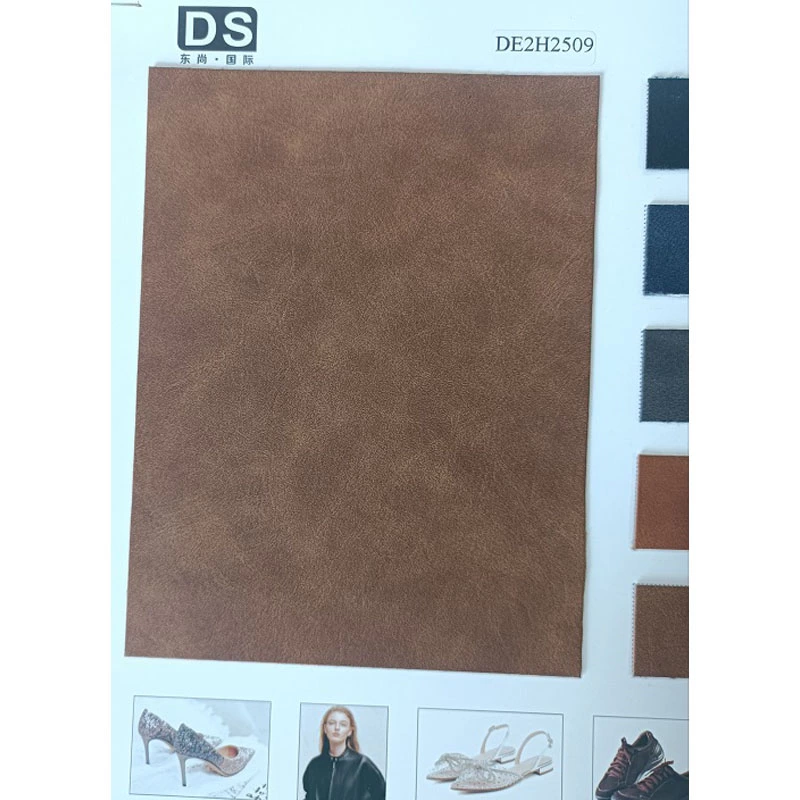

PVC , Semi PU Leather In the manufacturing process, the plastic particles must first be melted to make dough, which is evenly coated on the T/C knitted base according to the specified thickness, and then enters the foam furnace, which has the softness to adapt to the production of a variety of products, and is surface treated (dying, embossing, polishing, matting, grinding stone) at the same time.

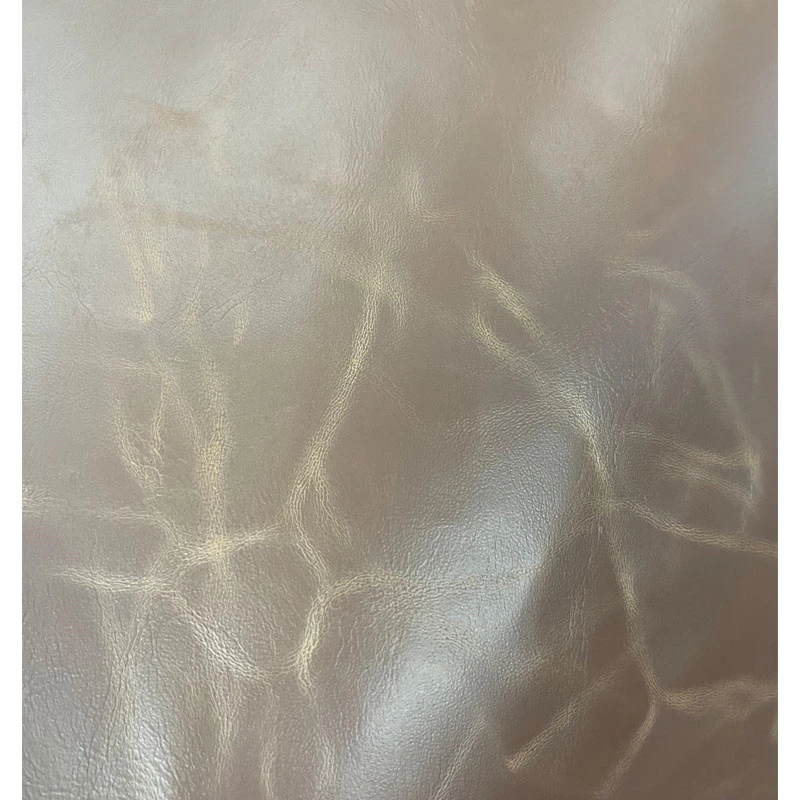

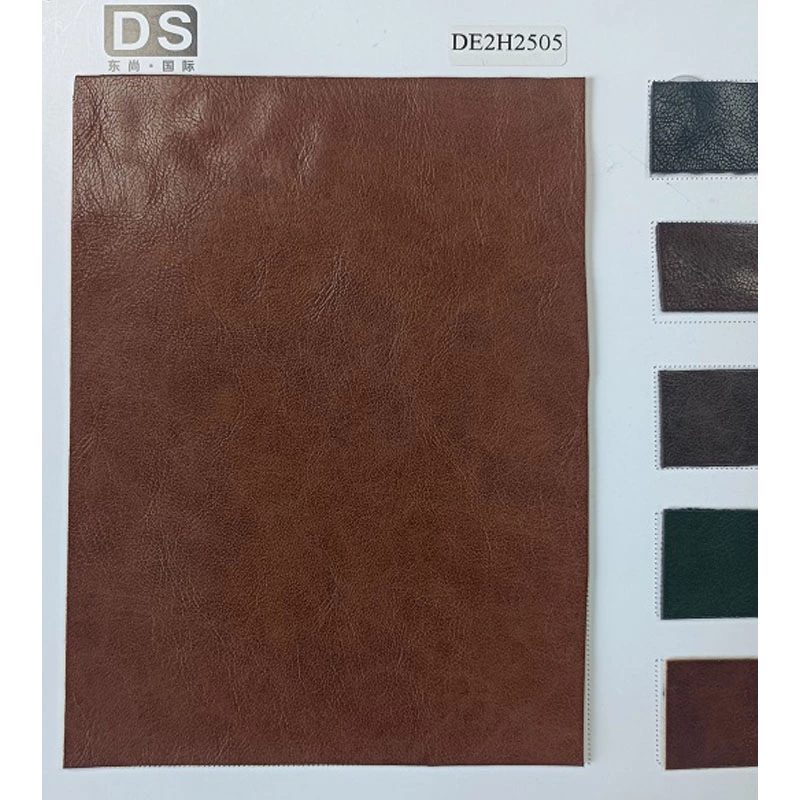

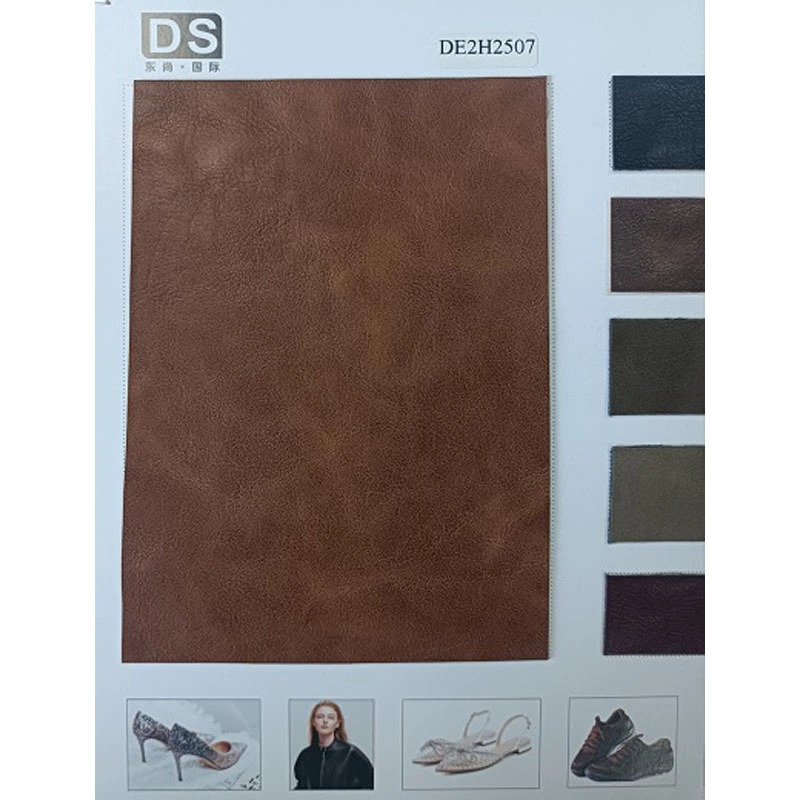

PU leather is more complicated than PVC leather in the manufacturing process. The base fabric of PU is a canvas PU material with good tensile strength, so it can not only be coated on the base fabric, but also include the middle base fabric, and the existence of the cloth that cannot be seen from the outside can be seen. The physical properties of PU leather are better than those of PVC leather, with tortuosity, softness, tensile strength, and breathability (PVC-free). The pattern on PVC leather is hot-pressed by a pattern roller made of steel. The pattern of PU leather is made by first sticking a hot sticker on the surface of the semi-finished leather with a pattern paper, waiting for cooling, and then separating the paper skin for surface treatment. The price of PU leather is more than double that of PVC leather, and the price of PU leather for some special requirements is 2 to 3 times higher than that of PVC leather. The pattern paper required for ordinary PU leather can only be discarded 4 to 5 times. Due to the long service life of the pattern roller, the cost of PU leather is higher than that of PVC leather. There are also some differences in the scope of application of these two materials. In the case of footwear, PVC leather is mostly used to make parts that do not bear lining or weight or children's shoes. PU leather can be applied to the fabric of footwear or the parts that bear weight. PVC leather is more commonly used in bags. Because the things in the bag are different from the feet in the shoes, they will not heat up. There is no need to bear personal weight.

PU leather

Due to the flexibility, ductility, toughness, instability affected by temperature, environmental friendliness, and non-compliance with the requirements of the social and commodity markets of PVC products, PU synthetic leather is produced.

Initially, PU leather has been developed and used unprecedentedly in clothing, laying a solid foundation for the diversification and multi-quality development of PU leather in the future. Then PU leather has achieved multi-quality development in bags, shoes and other products, but the production and manufacturing of PU synthetic leather is more complicated, and the price of raw materials is higher. While PU leather meets social needs, it also generates a corresponding high price.

The difference between PU and PVC is relatively easy. From the corner, the cost is much thicker than PVC, and the feel is also different. PU feels soft. PVC feels harder. It can also be burned with fire. The smell of PU is much lighter than that of PVC.