How To Maintain Pu Leather?

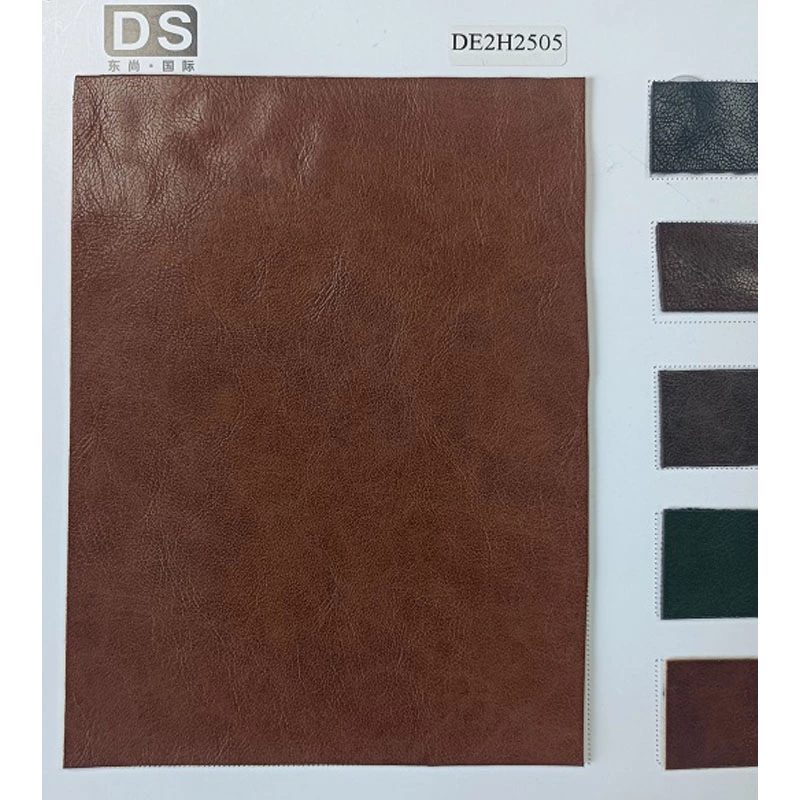

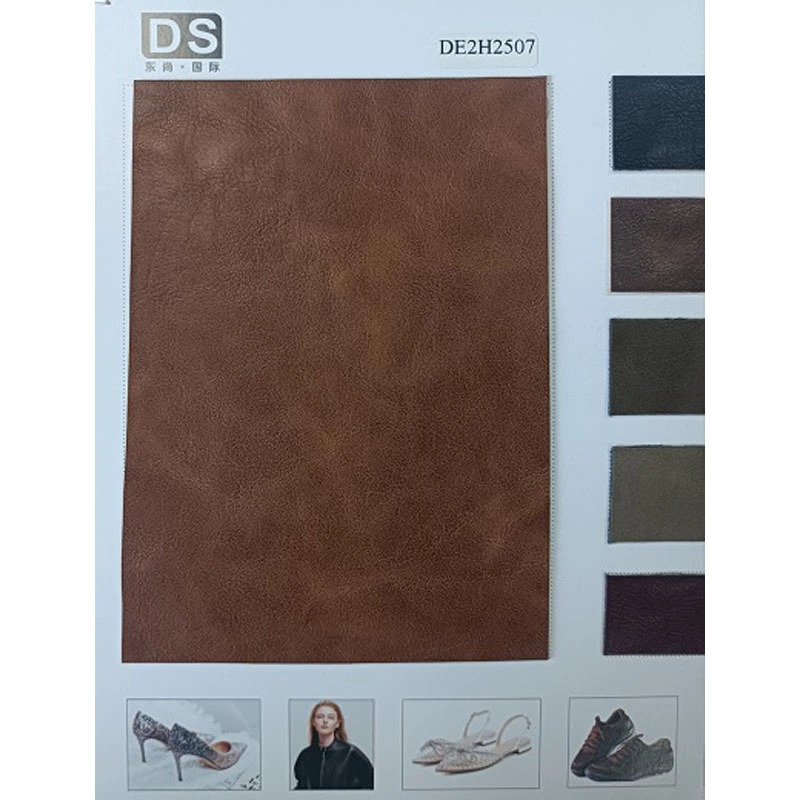

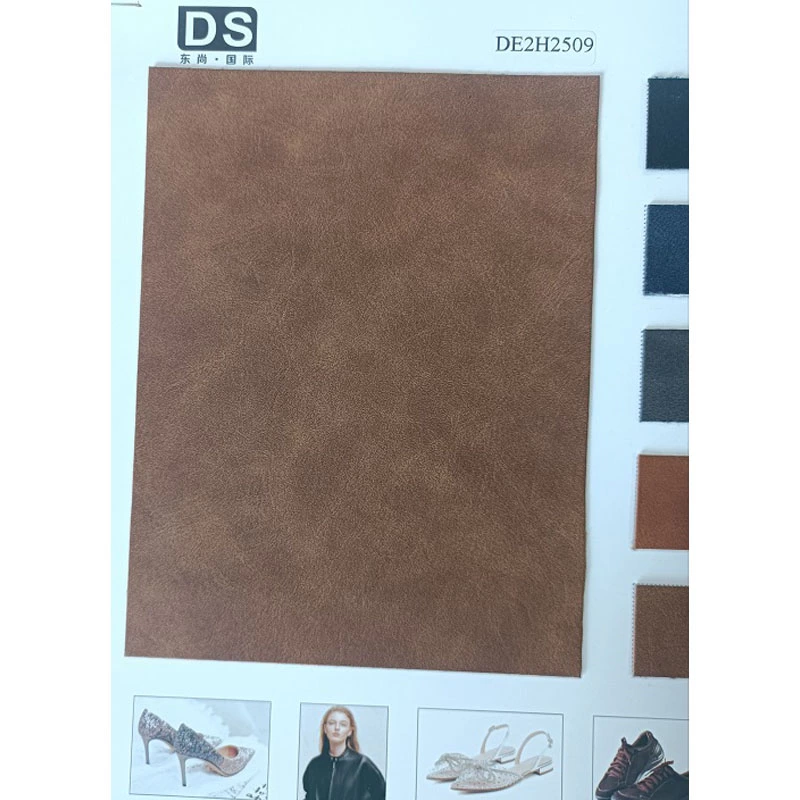

PU leather is the abbreviation of poly urethane in English, and its chemical Chinese name is "polyurethane". PU leather is the surface of polyurethane. It is widely used in bags, clothing, shoes, vehicles, and furniture decoration, and is recognized by the market. It has a wide coverage, large quantity, and many varieties, which traditional natural leather cannot meet. PU leather has good and bad quality. Good PU leather is more expensive than genuine leather, has good shaping effect, and bright surface!

What is the maintenance method of PU leather?

PU Leather cleaning method:

1. Do not touch water and detergent for cleaning, wipe with gasoline

2. Do not dry clean

3. Only washable, and the washing temperature cannot exceed 40 degrees

4. Do not expose to the sun

Cannot contact some organic solvents.

6. PU leather jackets need to be wrapped, so they cannot be folded

Natural leather has natural characteristics, so it is widely used in the production of daily necessities and industrial products, but with the increase of the world's population, human demand for leather has doubled, and the limited amount of natural leather can no longer meet people's needs. In order to solve this contradiction, scientists began to study and develop artificial leather and synthetic leather decades ago to make up for the shortcomings of natural leather. The research history of more than 50 years is the process of artificial leather and synthetic leather challenging natural leather.

Scientists started from studying and analyzing the chemical composition and organizational structure of natural leather, and entered PVC artificial leather from nitrocellulose varnished cloth, which is a first-generation product of artificial leather. On this basis, scientists have made many improvements and explorations, first of all, the improvement of equipment, and secondly, the modification and improvement of coating resin. In the 1970s, synthetic fiber non-woven fabrics appeared with needle piercing, mesh bonding and other processes, and the substrate had lotus root cross-section and hollow fiber, reaching a porous structure, which was consistent with the mesh structure of natural leather. At that time, the surface of synthetic leather was already a micro-tool group polyurethane layer, which could be comparable to the particle surface of natural leather. Therefore, the appearance and internal structure of PU synthetic leather gradually approached natural leather, and other physical properties were close to the indicators of natural leather, and the color was brighter than natural leather. It can be folded inward at room temperature for more than 1 million times, and it can also reach the level of natural leather at low temperature.

The emergence of ultra-fine PU synthetic leather is the third generation of artificial leather. The non-woven fabric of the three-dimensional structure network has created conditions for synthetic leather to surpass natural leather in terms of equipment. This product combines the newly developed PU sheet impregnation and composite layer processing technology with a perforated structure, giving full play to the huge surface area and strong absorption of ultrafine fibers, so that ultrafine PU synthetic leather has the inherent hygroscopic characteristics of ultrafine collagen fiber natural leather, so it can be comparable to natural leather in terms of internal microstructure, appearance texture, physical properties, and wearing comfort. In addition, ultrafine fiber synthetic leather exceeds natural leather in chemical resistance, quality uniformity, large-scale production and processing adaptability, waterproofing, fungal degeneration, etc. The various properties of synthetic leather have been proven to be irreplaceable by natural leather. From the analysis of domestic and foreign markets, synthetic leather has also replaced a large number of natural leathers with insufficient resources. The use of artificial leather and synthetic leather to decorate bags, clothing, shoes, vehicles, and furniture has been recognized by the market. Its wide range of applications, large quantity, and variety are not met by traditional natural leather.