Current Situation And Development Of Artificial Leather And Synthetic Leather In My Country

In recent years, the world's PU Leather industry center has gradually shifted to my country, prompting my country's artificial leather and synthetic leather industry to achieve rapid development. With the increase in consumers' environmental awareness and the increase in consumer demand, the artificial leather and synthetic leather industry is developing in the direction of ecological environmental protection and functional diversity. At present, ecological functional synthetic leather has become the development trend of the industry, and is relying on its own advantages to usher in a period of rapid development.

1. The development of my country's artificial leather and synthetic leather industry

Leather is one of the earliest materials of mankind. With the development of human society, the imbalance between the supply of natural leather and the growing demand of people has become more and more prominent. In order to solve the increasing shortage of natural leather and meet people's needs for the widespread use of various clothing fabrics, people began to use different chemical raw materials and methods to manufacture natural leather substitutes in the 1930s.

2. Artificial leather and synthetic leather industry has broad market prospects

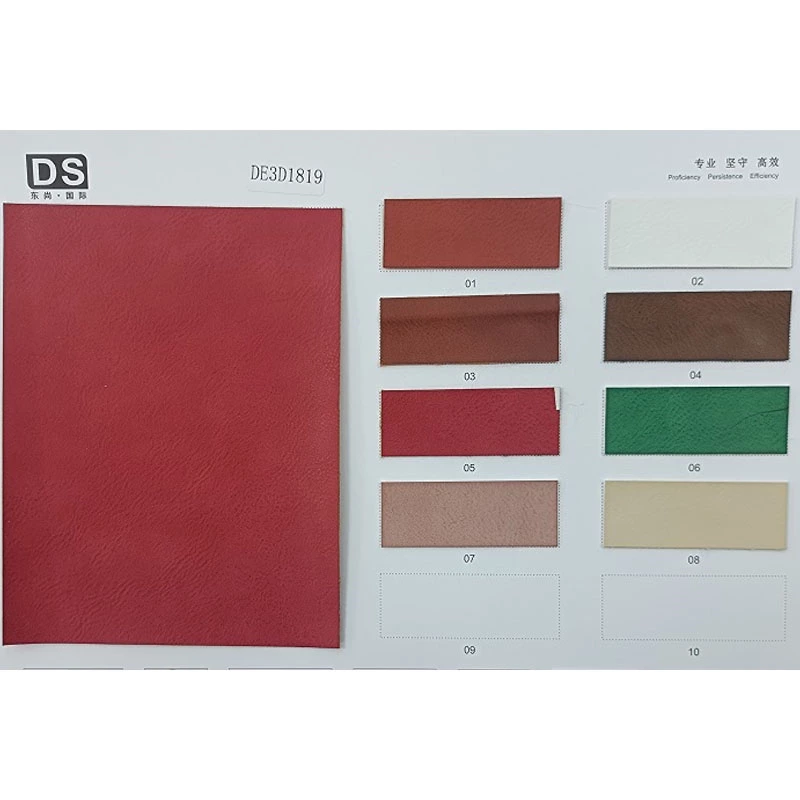

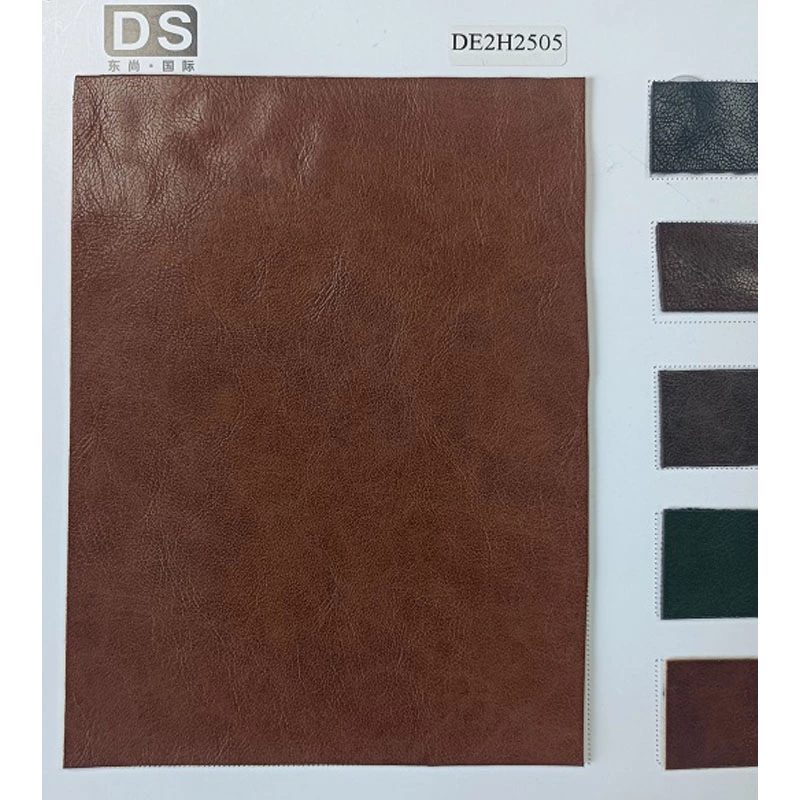

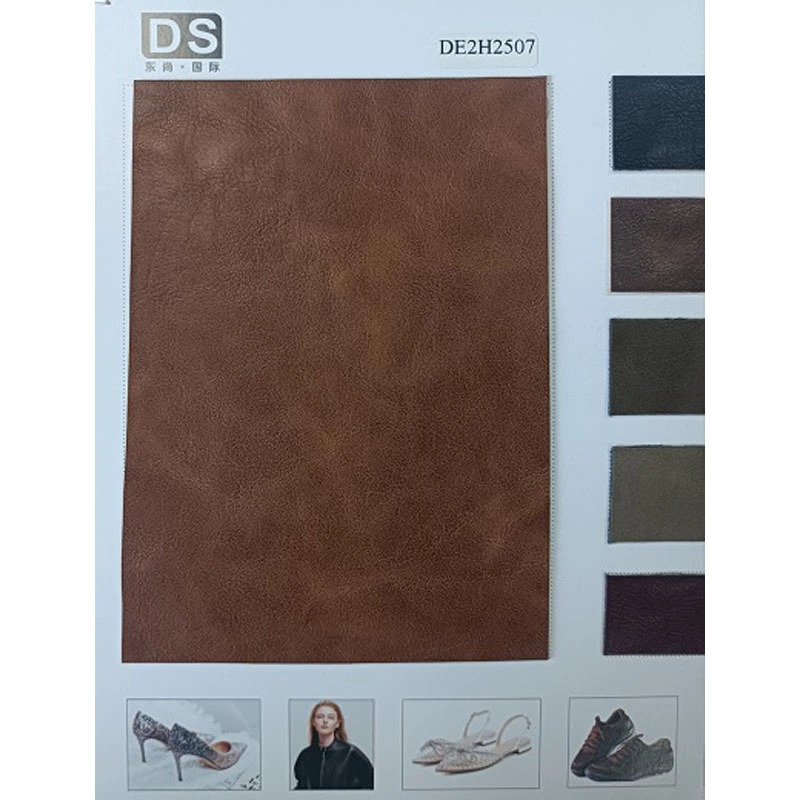

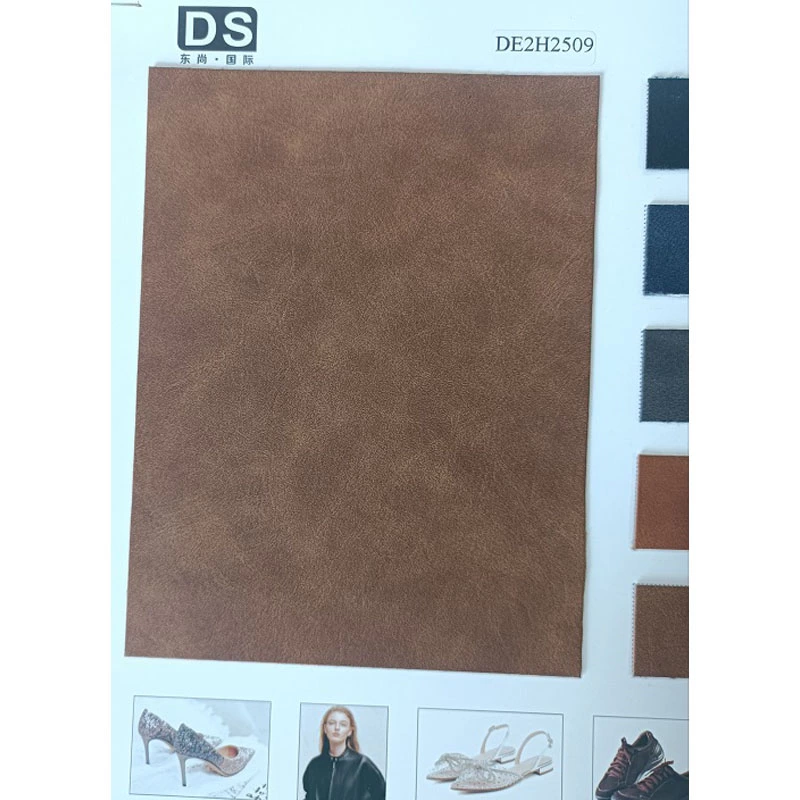

The application fields of artificial leather and synthetic leather involve all aspects of people's lives and have a broad demand market. Men's and women's shoes, sports casual shoes, children's shoes, fashion shoes, clothing, handbags and bags, sofa furniture, balls and sports goods, stationery documents, car interiors, jewelry boxes, handicraft packaging, etc. produced with it as materials have been increasingly recognized by the market. Its wide range of applications, large quantity, variety and high grade cannot be met by traditional textile materials and natural leather.

At present, the main demand areas for artificial leather and synthetic leather in the world are concentrated in China, South Korea, Malaysia, the Philippines, India, Pakistan, Bangladesh, Indonesia and other places in Asia; Germany, Belgium, Russia, Spain, Italy, Portugal and other places in Europe; Turkey, Morocco, Egypt, Syria, Jordan, Iran and other places in the Middle East; Mexico, Brazil, Peru, Guatemala, Colombia and other places in South America; and the United States, Canada and other places in North America. The global demand for artificial leather and synthetic leather is in a continuous growth.

3. Eco-functional artificial leather and synthetic leather have become the development trend of the industry

Natural leather, also known as genuine leather, is processed from animal skins. Common ones include pig leather, cow leather, sheep leather, horse leather, etc. The characteristics of natural leather are softness, breathability, wear resistance, high strength, high moisture absorption and water vapor permeability, but the resources are limited, the price is expensive, and the processing process is polluting. In addition, the shape of genuine leather is irregular, the thickness is not very uniform, and the surface is prone to damage.

Artificial leather and synthetic leather can be divided into PVC artificial leather and PU synthetic leather. Because the processing process is not limited by time and raw materials, the product has good uniformity, consistent width, and is easy to cut and process. In recent years, it has become a good material to replace natural leather. Among them, PVC artificial leather is mainly made by coating on the fabric base in the form of solution, suspension, plastisol or film. Its advantages are low price, rich colors and various patterns; PU synthetic leather has good elasticity in terms of chemical structure, is not easy to harden or become brittle, and has the advantages of rich colors, various patterns and long durability. Microfiber synthetic leather is a new generation of artificial leather. It uses non-woven fabric made of microfiber as the matrix and has a microstructure similar to natural leather - fine collagen fibers are entangled with each other. At the same time, polyurethane synthetic leather post-processing technology is used to produce an appearance similar to natural leather. Microfiber synthetic leather is close to genuine leather in appearance, feel and internal structure, and is even better than genuine leather in physical properties such as acid and alkali resistance, yellowing resistance, peel strength and bursting strength. It can be widely used in high-end clothing, shoemaking, sofa furniture, luggage, decoration and other industries. There are two main production processes: fixed island and unfixed island. The synthetic leather produced by fixed island technology has good dyeing uniformity and high mechanical properties, but poor softness and feel after raising; the synthetic leather produced by unfixed island technology is relatively soft and has a better feel after raising, but the strength is relatively low, and it is prone to uneven dyeing and poor color fastness. In addition, the raised fibers are easy to fall off and have poor anti-pilling performance. Microfiber synthetic leather currently faces certain problems and challenges such as high production cost, high energy consumption, and relatively difficult environmental pollution control during the dyeing process.

In recent years, eco-functional polyurethane artificial leather synthetic leather has gradually increased its share in the downstream market application of artificial leather and synthetic leather with its advantages of moderate price, high physical properties, multifunctionality, and eco-friendly. Eco-functional artificial leather synthetic leather refers to synthetic leather products that are both eco-friendly and have various excellent properties to meet the various needs of consumers.

The eco-friendly indicators of eco-functional artificial leather synthetic leather should meet the technical indicators of China's eco-synthetic leather labeling products, the technical requirements of China's environmental labeling products and the EU environmental standards.

The functionality of the product mainly includes physical and mechanical properties, such as peel strength, tensile load, tear strength, folding fastness, bursting strength, stitching strength, etc. In addition, it also includes flame retardancy, waterproof and breathable, antibacterial and mildew resistance, oil and stain resistance, acid and alkali resistance, hydrolysis resistance, high-frequency heat cutting resistance, etc. Different application fields have different requirements for the functionality of artificial leather and synthetic leather.

4. Analysis of the future development trend of China's artificial leather and synthetic leather industry

my country's artificial leather and synthetic leather have achieved rapid development in the past few years, but from the perspective of the industry as a whole, there are still many problems, such as small-scale production enterprises with poor environmental protection level, heavy pollution, low product added value, and insufficient innovation ability. Ecological functional polyurethane synthetic leather emphasizes both functionality and environmental protection, representing the future development direction of the synthetic leather industry. In the future development, enterprises should focus on improving overall strength, attach importance to product quality and technological innovation, increase R&D investment, improve the existing product technology level and industry environment, and provide the market with more and better ecological functional artificial leather and synthetic leather, so that my country's artificial leather and synthetic leather industry can continue to develop healthily.

VI. Market Forecast

1. Future Market Capacity

The forecast for the demand of PVC artificial leather from 2015 to 2020 is as follows: Unit: 100 million square meters

\

In the next few years, the market of PVC artificial leather and synthetic leather will grow at a relatively stable rate, and the average annual compound growth rate from 2015 to 2020 is expected to be about 10.49%, and the market demand in 2020 will be about 3.188 billion square meters.

The forecast for the demand of artificial leather, synthetic leather and microfiber synthetic leather from 2015 to 2020 is as follows: Unit: 100 million square meters

\

In the next few years, the market of artificial leather and synthetic leather will grow at a relatively stable rate, and the average annual compound growth rate from 2015 to 2020 is expected to be about 9.27%, and the market demand in 2020 will be about 6.7 billion square meters.

The forecast of demand for eco-functional synthetic leather in my country from 2015 to 2020 is as follows:

In the next few years, eco-functional synthetic leather will enter a period of rapid growth, with an estimated annual compound growth rate of about 16.30% from 2015 to 2020, and a market demand of about 585 million square meters in 2020.

Since my country has included "polyvinyl chloride ordinary artificial leather production line" in the restricted development projects, and "green barrier" countries such as Europe, the United States and Japan have also greatly restricted the consumption of PVC artificial leather. Therefore, in the future development, the demand growth rate of eco-functional PUD synthetic leather produced by the company will increase significantly.